By Yassine Taha and Mostafa Benzaazoua

Innovative strategies to improve phosphorus efficiency along the mining–use–recovery pathway are highlighted through the approaches developed by OCP Group and UM6P’s Geology & Sustainable Mining Institute. Key measures include advanced orebody modeling for selective extraction, sensor-based ore sorting, water recycling, and desalination. Near-zero-waste mining creates value from low-grade ores and legacy waste that are integrated with circular economy principles and mine rehabilitation. These approaches offer a roadmap for sustainable phosphate management and environmental stewardship.

Phosphorus (P) is an essential and irreplaceable nutrient for all living organisms, forming the backbone of global food production through fertilizers. However, it is a non-renewable resource extracted almost exclusively from phosphate rock deposits that are geographically concentrated in a few regions, particularly Morocco. The growing demand for food and the expected increase in global population have made the efficient management of P along its entire life cycle, from mining to its end-of-life recovery, an urgent global challenge.

Current estimates indicate that less than 20% of mined P eventually reaches human consumption due to inefficiencies across the mining, processing, agricultural, and waste management stages. The rest is lost as waste rock, tailings, or dispersed into soils and water bodies. Consequently, improving global P efficiency requires a holistic approach that integrates orebody knowledge, optimized production chains, and sustainable waste valorization. Promising approaches being developed by the Geology & Sustainable Mining Institute (GSMI) of UM6P along with OCP Group are enhancing P efficiency along the mining–use–recovery pathway.

Orebody knowledge and characterization

Comprehensive orebody knowledge forms the foundation of sustainable mining. It enables optimized extraction, efficient beneficiation, and strategic waste management. Phosphate deposits, being sedimentary and highly heterogeneous, often contain a complex assemblage of mineralized layers interbedded with non-phosphatic lithologies such as carbonates, flints, and clays. Understanding this spatial variability is essential to reduce P losses and to valorize the full range of materials present in the orebody.

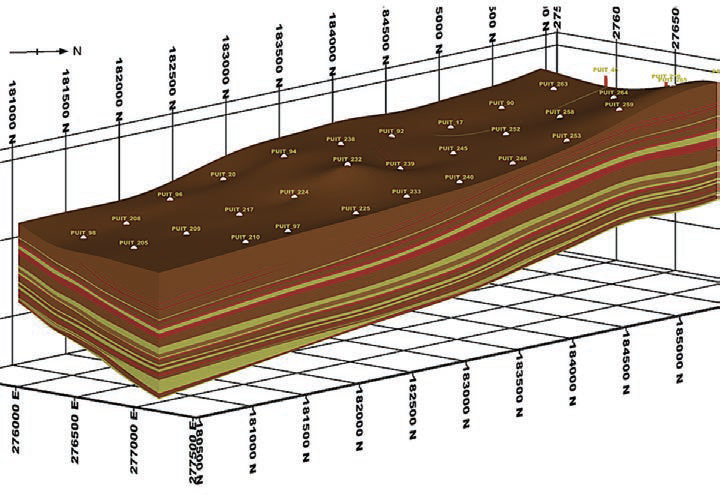

OCP has undertaken a systematic drilling and core-sampling campaign across its main phosphate basins (Khouribga, Benguerir and Gantour). This program is coupled with multi-technique sample characterization, combining mineralogical, geochemical, and physical analyses to build 3D digital geological models of phosphate deposits (Fig. 1). These digital twins integrate data on phosphate resource distribution, physical rock properties, and the presence of bonus or penalizing elements such as magnesium (Mg), iron (Fe), or carbonates. The resulting orebody models enable predictive mine planning and selective extraction to maximize recovery while minimizing dilution and waste generation.

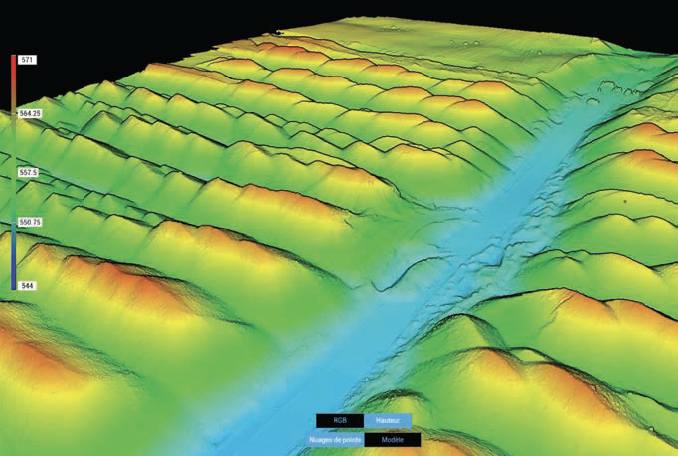

Furthermore, OCP is exploring P recovery from past mining wastes. Historical mining activities have generated large waste volumes, with an average of 3 t of waste rock per t of phosphate rock. These materials, although previously uneconomic, are being reassessed using advanced teledetection methods (satellite imagery, drone-based mapping) and systematic spoil sampling (Fig. 2). Several studies are currently underway to assess the recovery potential of these materials through lab-validated screening and sensorbased sorting flowsheets, which are being upscaled to the pilot level. Phosphate mining operations should aim to separately deposit and document waste materials to facilitate future re-extraction when recovery becomes feasible, thus advancing circular resource management and preventing permanent orebody losses.

Optimization of phosphorus flows along the mine value chain

Phosphorus efficiency cannot be achieved without optimizing flows along the entire mining value chain—from extraction and beneficiation to transportation and processing. Major inefficiencies typically arise during the upstream operations (extraction and crushing), as well as during beneficiation (screening, washing, flotation), where significant P is lost in the tailings or diluted by nonphosphatic material.

To address these inefficiencies, OCP and GSMI are developing integrated solutions that focus on reducing losses, lowering energy and water consumption, and increasing recovery rates. One of the most promising approaches is the use of sensor-based ore sorting technologies.

Ore sorting technologies

Ore sorting involves the separation of mined material based on physicochemical properties detected by sensors such as X-ray transmission (XRT), near-infrared (NIR), or laser-induced breakdown spectroscopy (LIBS), etc. These systems can distinguish phosphate-rich particles from waste based on density, elemental composition, or color, allowing for real-time removal of non-valuable material prior to grinding and flotation. The benefits are multiple:

- Reduced energy and water consumption since less material needs to be processed downstream;

- Increased P2O5 recovery by minimizing dilution with barren lithologies;

- Extended orebody life through the economic inclusion of lower-grade ores; and

- Reduced tailings volume and environmental footprint.

Preliminary trials in sedimentary phosphate ores from OCP’s mines have demonstrated that pre-sorting can increase recovery efficiency. In combination with improved orebody models, ore sorting can create a dynamic and adaptive mine plan, focusing on the right material at the right time.

Water efficiency in beneficiation

Water management remains one of the most critical sustainability challenges in phosphate rock processing. A key strategic objective for the phosphate industry is to progressively substitute natural freshwater sources with alternative water resources. Today, more than 80% of the water used in phosphate mining and beneficiation operations can be sourced from non- conventional origins, including seawater desalination plants, treated and recycled wastewater, and recovered process water.

Within the beneficiation circuit, particularly during the flotation and thickening stages, advanced flocculation-thickening systems allow the recycling of over 75% of process water, thereby reducing both freshwater intake and the environmental footprint associated with tailings storage facilities. Ongoing developments aim to further enhance water recovery by transitioning towards dry tailings management through filtration technologies, enabling near-total recycling of process water and minimizing water loss by evaporation.

In parallel, phosphate producers are increasingly adopting bio-based reagents in mineral processing to reduce dependence on imported chemical reagents, enhance supply sovereignty, and lower Scope 3 (value chain) greenhouse gas emissions. This integrated approach, combining alternative water sourcing, closed-loop recycling, and green chemistry, reflects a comprehensive commitment to sustainable water and resource management in the phosphate mining sector.

Waste valorization and the near-zero waste approach

Mining and beneficiation generate large volumes of solid wastes, which have traditionally been considered uneconomic or inert. However, these materials often contain valuable minerals that can be recovered or repurposed, enabling a shift toward near-zero-waste mining.

The GSMI teams are pioneering a selective mining methodology that aims to extract, classify, and store different lithological layers separately for future valorization. In typical sedimentary phosphate deposits,

the orebody includes:

- Phosphate rock layers (economic mineralization)Low-grade and difficult to exploit phosphate layers;

- Calcite-rich layers;

- Dolomite-rich layers;

- Clay-rich layers; and

- Mixed layers.

Valorization pathways

The traditional extraction approach focuses solely on the phosphate layers, while the others are mixed and dumped as overburden or waste. The selective mining strategy proposes to extract and stockpile each lithology separately, creating a diversified resource base for secondary processing.

- Calcite-rich layers: can be transformed into value-added products such as animal feed additives (DCP, MCP), cement, and lime-based construction materials. Pilot-scale results have already confirmed their suitability for such applications.

- Dolomite-rich layers: have potential uses in aggregates, magnesium metal production, struvite synthesis, and feed-grade phosphates.

- Clay-rich layers: can serve as precursors for ceramics, eco-cements, or geopolymer materials for construction and environmental remediation.

- Low-grade phosphates: may be blended or upgraded through beneficiation or used in slow-release fertilizers.

Recovery from legacy wastes

As previously mentioned, historical mine waste dumps containing 10% P2O5 or more are being reconsidered as secondary resources. Through screening and ore sorting, the P-bearing fractions can be concentrated and reprocessed using the same beneficiation circuits as primary ores. This strategy not only recovers P but also reduces the long-term footprint of waste storage sites.

Integration with circular economy principles

These valorization initiatives embody a circular approach to mining, ensuring that every fraction of the orebody contributes to economic value. Instead of viewing mining residues as environmental liabilities, they become secondary raw materials for multiple industries. This transition supports local economies, reduces landfill requirements, and aligns with global sustainability goals such as the United Nations Sustainable Development Goals (SDGs 9, 12, and 13).

Restoration and rehabilitation of mine waste landfills

Sustainable phosphate mining extends beyond resource extraction to include the restoration and rehabilitation of mine waste landfills. Modern mine reclamation practices aim not only to stabilize terrain and prevent erosion but also to rebuild functional and resilient ecosystems. Early integration of rehabilitation strategies into mine planning enables reshaping of waste landforms, selective cover application, and the reintroduction of native or drought-tolerant vegetation to restore ecosystem services while minimizing irrigation needs. Emerging approaches promote value creation through restoration, transforming reclaimed lands into productive assets such as agroforestry zones, solar farms, or biodiversity corridors.

In parallel, research focuses on enhancing soil health and reducing water use through the reuse of mine-derived materials and the development of engineered soils combining tailings, clays, and organic amendments. These substrates improve fertility and water retention, enabling vegetation growth under arid conditions. The use of customized fertilizers formulated from recovered P and local minerals supports nutrient efficiency while closing material loops. By integrating soil restoration, efficient water management, and circular resource use, the phosphate mining sector can transform post-mining landscapes into sustainable ecosystems that generate environmental and socio-economic value.

Conclusion

Enhancing global P efficiency requires a systemic transformation of the mining–use–recovery pathway. OCP’s approach demonstrates how a combination of data-driven orebody knowledge, technological innovation, and circular resource management can drastically improve resource efficiency and environmental sustainability.

Through systematic drilling and 3D digital mapping, OCP is unlocking a precise understanding of phosphate deposits to enable selective extraction and long-term planning. Ore sorting and optimized beneficiation are reducing energy, water and P losses, while water recycling and desalination initiatives secure the sustainability of operations in arid environments. Simultaneously, the valorization of both current and historical wastes through a selective mining methodology is transforming the concept of waste into opportunity.

Collectively, these efforts represent a paradigm shift toward “near-zero-waste” phosphate mining, ensuring that the world’s largest phosphate reserves are managed responsibly and efficiently. By closing the loop between extraction, processing, and recovery, OCP’s integrated model provides a tangible roadmap for global P sustainability—linking mineral efficiency with food security and environmental stewardship.

Dr. Taha (Yassine.TAHA@um6p.ma) and Dr. Benzaazoua are with the Geology and Sustainable Mining Institute (GSMI), University Mohammed VI Polytechnic (UM6P), Benguérir, Morocco.

Cite this article

Taha, Y., Benzaazoua, M. 2025. Enhancing Global Phosphorus Efficiency Along the Mining–Use–Recovery Pathway. Growing Africa 4(2):5-8. https://doi.org/10.55693/ga42.EVGF3735